Mooring and docking

by Keith Warren, Back Cove Yachts 24 Apr 2018 09:37 PDT

Fenders © Back Cove Yachts

Among the best perks of my position as Engineering Manager at Back Cove is performing sea trials to validate a new model or engineering change.

Launching a boat that is fresh off the production floor is always exciting, though there have been moments of nervousness as I departed the dock knowing one of our infamous New England Nor'easters was brewing. But then again, what better time for a sea trial?

Nevertheless, after a rough-weather trial, it is always a relief once the boat returns to harbour and is securely tied. I take comfort that any Back Cove or Sabre will be safe and sound at the dock during a storm, primarily because of how the strong points are designed.

Technical Details

All of our models meet ABYC guidelines so, if we use the Back Cove 41 as an example, all mooring cleats and the structure to which they are attached must withstand a working load of almost 10,000 pounds. Maybe this seems like a lot to ask from a single metal part, but a fully-loaded Back Cove 41 weighs about 30,000 lbs, and the 5/16" diameter mounting posts on our stainless steel cleats can withstand a 35,000-pound pull-force before failure.

Since it is unlikely the cleat itself will fail, detailed attention is given to the strong points to which the cleat is mounted.

Cleat Mounting

All Back Coves and Sabres have cleats mounted into solid fiberglass. The mounting studs pass through ½" of solid fiberglass and a ½" backing plate. We finish the connection with stainless washers and nylon lock nuts. When force is applied to the cleat, it is distributed from the threads to the nut, then to the washer, the backing plate, and finally to the fiberglass deck. It would be a terrifying force that could rip these cleats off the deck, and I hope never to witness a storm generating those conditions.

Dock Lines

Dock lines and fenders are the final elements necessary to make any boat genuinely secure at the dock, no matter the conditions. For many boaters; a proper spring line can be masterfully used to maneuver a vessel under challenging conditions. Because all Back Cove yachts have a bow thruster, and many have the optional stern thruster, using spring lines to move into or off of the dock is typically not necessary. However, midship forward and aft spring lines to secure a vessel for long-term docking are advantageous.

Once spring lines are in place, a boat can easily be moved forward/aft to make the best use of dock space. Finally, adding bow and stern lines keeps the vessel tight to the dock. I prefer to use the outside transom cleat to maximize access to the swim platform and transom door as illustrated in the drawing above.

We have significant tidal changes in Maine, so short spring lines perpendicular to the dock are usually avoided, as they do not allow an adequate vertical range of movement. The 10" deck cleats mounted to the toe-rail on all Back Coves are good for 5/8" braided dock lines and can accept two spliced loops each.

When tying up to a mooring, I recommend a 5/8" rope bridle to split the loads between the starboard and port forward cleats. The length of the bridle and painter should be 2.5x the height of the strong point above the waterline.

Fenders

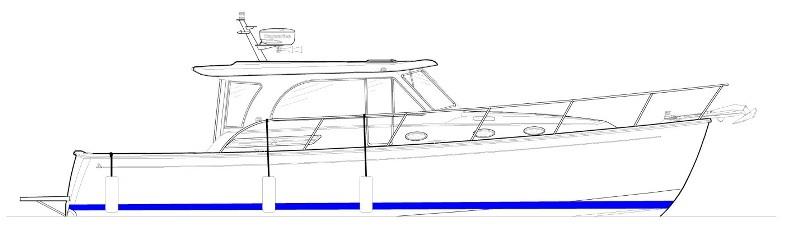

Last but not least, I recommend three fenders on the docked side of the vessel, as illustrated below. The first located aft on the pop-up cleat (on 2016 and newer Back Coves), one amidships at the beamiest part of the hull and one somewhere in between on the rail or stanchion. I like to make my fender whips out of ½" dock line, so they are long enough to tie up to the highest part of the bow rail. Using the bow rails to tie off the fenders also keeps the cleats free for dock lines. Felt fender covers, of course, add to the presentation of the boat and cover up smudges on the unprotected rubber fender.

Now that we know everything is secure boat-side, how reliable do the dock-side cleats look at your favorite tie-up spot?